Please note – A residential driveway must be properly constructed in order to be a good investment. The information contained in this chapter is intended as a general guide for the homeowner on the design and construction of asphalt concrete residential driveways. These driveways are simple and economical to build, and a driveway that is correctly designed and constructed will give many years of service with little or no maintenance.

Please note – A residential driveway must be properly constructed in order to be a good investment. The information contained in this chapter is intended as a general guide for the homeowner on the design and construction of asphalt concrete residential driveways. These driveways are simple and economical to build, and a driveway that is correctly designed and constructed will give many years of service with little or no maintenance.

The homeowner’s decision to pave his driveway is sometimes made many years after his home is constructed and frequently incorporates an existing crushed stone or gravel driveway. There are certain special considerations for this type of paving that are specifically addressed in this section, as is resurfacing existing asphalt driveways.

The homeowner’s decision to pave his driveway is sometimes made many years after his home is constructed and frequently incorporates an existing crushed stone or gravel driveway. There are certain special considerations for this type of paving that are specifically addressed in this section, as is resurfacing existing asphalt driveways.

For the homeowner that has an existing aggregate or gravel driveway, this page will act as a guide the necessary steps to pave over the existing driveway with asphalt concrete.

Choosing a Contractor

It is important to work with a reputable competent asphalt contractor with experience in constructing driveways. Any contractor going door-to-door with a truck of asphalt he wants to install “before it cools down” (and is willing to give a “good price”) is not a reputable contractor. A homeowner should have a contract that clearly specifies utility protection, drainage, subgrade preparation, base construction, and asphalt course (including pavement thickness).

It is important to work with a reputable competent asphalt contractor with experience in constructing driveways. Any contractor going door-to-door with a truck of asphalt he wants to install “before it cools down” (and is willing to give a “good price”) is not a reputable contractor. A homeowner should have a contract that clearly specifies utility protection, drainage, subgrade preparation, base construction, and asphalt course (including pavement thickness).

Homeowners generally do not have the benefit of strict specifications, trained inspectors, and the technical expertise that the public contracting agencies have at their disposal to control the project. The following tips may be helpful in selecting a reliable contractor and obtaining the best possible driveway structure.

- Select a contractor known for high-quality work and who has an established reputation in the community.

- Obtain proposals from more than one contractor to ensure that all are bidding on the same type of mix and construction. For true and valid comparisons to be made, all proposals should cover the same units.

- When discussing a project, be sure that the thicknesses agreed on are minimum compacted thicknesses.

- Visit pavement projects built by the prospective contractors and talk with the owners of the projects.

- Insist on a written contract or agreement, in addition to any guarantee offered by the driveway contractor. Whenever possible, make provision to retain some portion of the payment due to the contractor until there is complete satisfaction with the quality of the finished driveway.

Placement considerations

Aesthetic objects such as trees and rocks should be preserved whenever possible. Care must be taken to locate the driveway away from trees and shrubs whose root system may affect the pavement as they grow. Also, to avoid unsightly cuts in hilly areas, driveways should generally conform to the terrain. Where the property will accommodate it, a curving driveway will be more attractive. A curved driveway should be increased in width on sharp curves.

Minimum Pavement Widths and Radii

One of the most important considerations for residential driveways is the width of the pavement. The absolute minimum pavement width for a single automobile width is eight feet (8′), with ten feet (10′) being more desirable. When both pedestrians and an automobile will be using the driveway, the minimum recommended pavement width is twelve feet (12′). For two-car driveways, a minimum pavement width of twenty feet (20′) will permit the unobstructed opening of automobile doors on all sides.

The minimum radius for a right angle, such as where the driveway meets the street, is six feet (6′), with eight feet (8′) being preferable.

Pavement Thickness

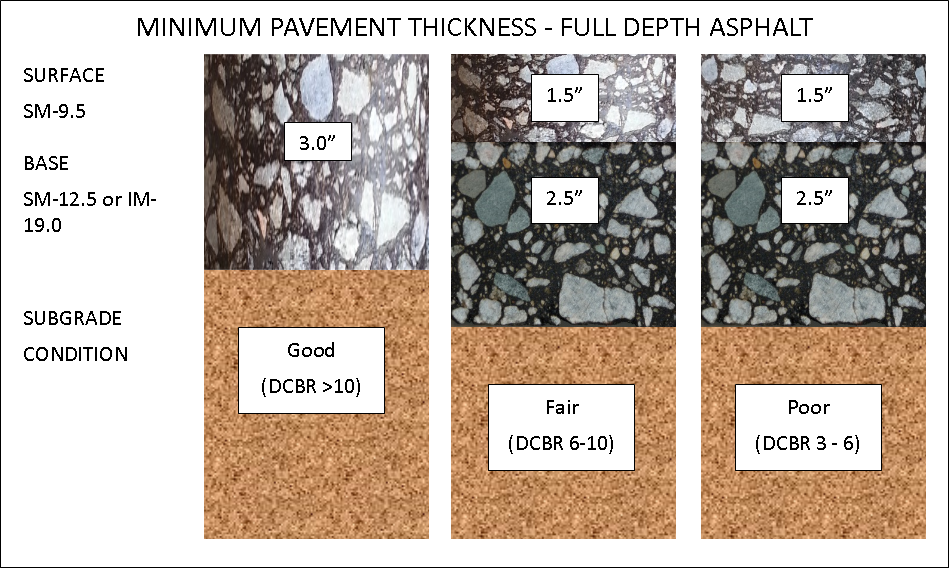

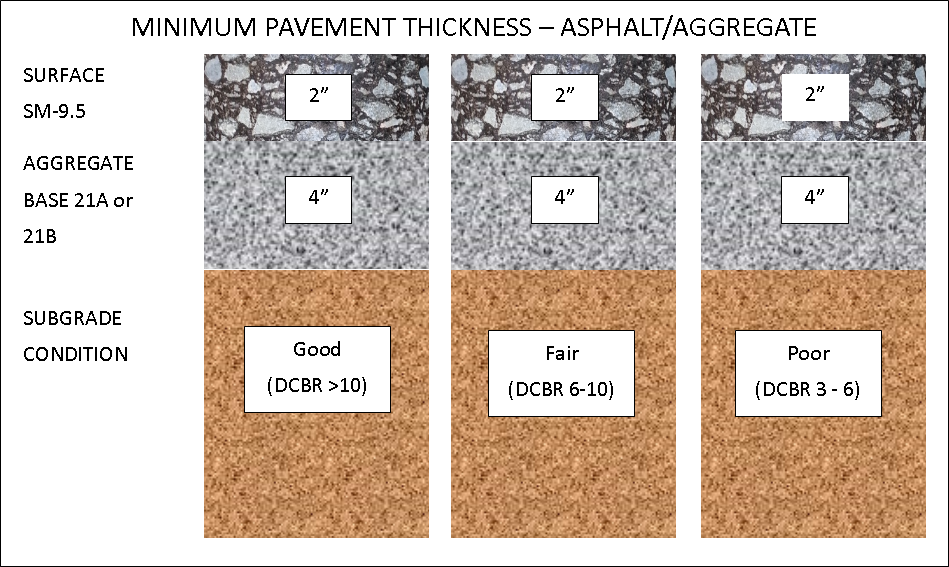

Recommended minimum pavement thicknesses are given in this chapter for various subgrade conditions using both full-depth (all asphalt) and composite pavements (asphalt over an aggregate base). These values are minimum compacted thicknesses. It may be necessary to increase these thicknesses to accommodate specific design requirements. Any contract for residential driveway construction should be worded accordingly.

Subgrade Preparation

Because the subgrade must serve both as a working platform to support construction equipment and as the foundation for the pavement structure, it is most important to see that it is properly compacted and graded. A visual examination will usually reveal the adequacy of elevation. The load-supporting characteristics of the existing subgrade soil should be carefully evaluated. Pavement design should be developed based on these evaluations coupled with previous experience with similar type materials.

All underground utilities should be protected or relocated prior to grading. The driveway should be located away from trees and bushes whose growing root systems may damage the pavement in future years.

All topsoil should be removed and low-quality soil must be improved by adding asphalt or other suitable admixtures such as lime or granular materials.

The areas to be paved should be treated with a soil sterilizing agent to inhibit future flora growth after all rock, debris, and vegetation matter has been removed. Grading and compaction of the area should be completed in such a manner as to prevent yielding areas or pumping of the soil. A large truck driven over the area will give an indication of any “soft spots”. Should a weak spot be discovered, the material should be removed and replaced with six inches (6″) compacted crushed stone or three inches (3″) compacted asphalt concrete. In case of extremely poor subgrade, it may be necessary to remove the upper portion of the subgrade and replace it with the selected material. When finished, the graded subgrade should not deviate from the required grade and cross section by more than one-half inch (1/2”) in ten feet (10′).

Drainage

Good drainage is important for pavement durability and long life. The surface of the driveway should blend to the contour of the existing ground so that the surface water runs over it or away from it in its natural course. In flat areas, the driveway should have a minimum slope of two percent (2%) or a crown not less than one-quarter inch per foot (1/4”/ft.) so that all surface water will drain off. Drainage from roof downspouts, patios, and walkways should, if feasible, be piped well away from the edge of the driveway. In some cases, pipe cross drains may be needed to take the water under the driveway. Under no circumstances should water be allowed to stand on the pavement or at the pavement edges.

Generally, an underdrain system is not required on full-depth asphalt pavements, even over poor soil or In certain other undesirable drainage conditions. However, an underdrain system may be required if the driveway pavement is constructed on an untreated aggregate base.

Base Construction (Asphalt)

Prior to placement of the asphalt concrete base course, the subgrade should be graded to the established requirements, adequately compacted, and all deficiencies corrected. The asphalt concrete course should be placed directly on the prepared subgrade in one or more lifts, spread, and compacted to the pavement thickness indicated on the plans or established in the contract. (Compaction of asphalt mixtures is one of the most important construction operations contributing to the proper performance of the completed pavement, regardless of the thickness of the course being placed. This is why it is so important to have a properly prepared subgrade against which to compact the overlying pavement.)

The asphalt concrete should meet Virginia Department of Transportation Specifications for the mix type specified.

Base Construction (Aggregate)

The subgrade must be graded to the required contours and grade in such a manner as will ensure a hard, uniform, well-compacted pavement structure. All deficiency corrections and drainage provisions should be made prior to constructing the aggregate base.

The crushed aggregate base course should consist of one or more layers placed directly on the prepared sub-grade, spread, and compacted to the uniform thickness and density as required on the plans or established in the contract. Absolute minimum crushed aggregate thickness is four inches (4″). All crushed aggregate material should be of Virginia Department of Transportation approved type and suitable for this application.

Tack Coat

Prior to placement of successive pavement layers, the previous course should be cleaned and, if needed, a tack coat of diluted emulsified asphalt applied. The tack coat may be eliminated if the previous course is freshly placed and thoroughly clean.

Asphalt Surface Course

Material for the surface course should be asphalt concrete placed in one or more lifts to the true line and grade as shown on the plans or established in the contract. Unless otherwise noted, the asphalt concrete should conform to Virginia Department of Transportation’s Specifications for Asphalt Concrete of the type specified. Any irregularities in the surface of the pavement course should be corrected directly behind the paver. Rolling and compaction should start as soon as the material can be compacted without displacement and continued until thoroughly compacted and all roller marks disappear. Improper compaction can result in rutting of the driveway over time.

Sealing

It is not usually necessary to seal the surface of a newly-constructed asphalt concrete driveway. When the pavement is properly constructed, the driveway should afford many years of service before a thin application of driveway sealer containing mineral grit (available at hardware stores) becomes desirable to improve the surface texture, seal small cracks, and update the appearance. If the pavement is not properly compacted during construction, a surface sealer may be needed within two to four years.

Paving Existing Aggregate Driveway

The required asphalt pavement thickness for surfacing an existing gravel or aggregate driveway may be taken from the table showing asphalt and aggregate base construction. However, all existing aggregate driveways must be graded and treated with a non-toxic commercial soil sterilizing agent prior to paving. Also, a determination of the depth of existing stone must be made. Should that determination reveal an aggregate depth less than required minimum thickness shown in the table for aggregate base material, additional stone or pavement thickness will be required.

Resurfacing Existing Asphalt Driveways

After many years of service, the homeowner may want to repair and resurface an asphalt driveway to correct original construction errors, oxidation, cracking, and automobile fuel or oil spillage. All weak areas should be repaired with proper patches prior to resurfacing. Areas, where fuel spillage and other petroleum products have softened the asphalt pavement, must be removed and patched. Structural patches should be designed and constructed with full depth asphalt concrete to ensure strength equal to or exceeding that of the existing pavement. Careful and correct preparation of the existing pavement, prior to the construction of smoothing or strengthening overlays, is essential for good construction and maximum overlay performance. Requirements for correct preparation of existing pavements for overlays vary with the pavement age, condition, and use. For this reason, it is recommended that a competent asphalt driveway contractor is consulted for required pavement repairs and overlay thickness. It is recommended, however, that the overlay have a minimum compacted thickness of at least one inch (1″).

Design Considerations

When designing a driveway several considerations must be made by the homeowner. First and foremost, how wide does the driveway need to be? In many cases, the minimum width is 8 feet. If the driveway leads to a garage, then the driveway is at least the same width as the garage opening. As a general rule of thumb, a 10-foot wide driveway will accommodate one car. To park multiple cars side by side, the parking area of the driveway should be increased by 10 feet per car to allow for the opening of doors.

For the length of the driveway, the width can vary. In general, the width increases at the parking area and narrows down along the drive length. Where the drive intersects the roadway, a minimum radius of 6 feet should be installed.

Drainage

Two of the most important considerations in designing a pavement are traffic and drainage. If either is not accounted for in the pavement design, then the pavement structure will either be over-designed (and money wasted) or under designed (and result in premature and continual maintenance). Drainage impacts pavement performance when the subgrade materials and pavement layer materials are saturated and lose strength. Water that falls on the pavement surface must be drained to curb and gutter systems or ditches. Water penetrates the pavement from the surface, infiltrates from the sides of the road, or rises from under the pavement should not be allowed to compromise the overall strength.

To account for surface water drainage, it is important that the driveway is constructed with a crown or cross slope. Typically, a crown is placed in the center of the driveway and the pavement is sloped 2% in each direction. Occasionally, the pavement will be super-elevated where one side of the driveway is higher than the other. In either case, the pavement must be sloped to keep water from ponding on the surface.

For subsurface water, the approach to address varies based on the project. In some situations, underdrains are placed to intercept water that may flow under a pavement. This water is then allowed to flow out into a ditch or is put in a stormwater system. In many cases where the subgrade becomes weaker due to water, the subgrade is stabilized with a binding agent, removed and replaced with a stronger material, covered with a stabilization fabric prior to placing the next pavement layer, or the next pavement layers are made thicker. For most driveways, underdrains and stabilization are not necessary.

Subgrade Type and Strength

The subgrade type and strength will influence the overall pavement structure. Prior to construction of the driveway, all of the topsoil should be removed. Additional soil should be removed to accommodate the final driveway pavement.

Once the topsoil and additional soil are removed, the subgrade must be compacted with a roller. After the compaction, a large truck should be driven over the drive’s subgrade to look for any soft spots. Soft spots should be removed and replaced or stabilized.

The final step with the subgrade is treating the area with a soil sterilizing agent. This will keep vegetation from growing through the pavement.

Traffic

Cars and light-duty trucks are the normal traffic for a driveway. These vehicles do not normally cause pavement damage. At times, a heavy truck may use the driveway such as a construction delivery truck or concrete ready-mix truck. These heavy trucks will damage a driveway. If these trucks must use the driveway, it is recommended to wait until a time of the year when the pavement and soil is either dry or frozen.

Pavement Structure

The pavement structure and materials used will change as a function of subgrade strength and construction approach. Some projects will use full-depth asphalt (i.e., asphalt placed directly on compacted subgrade) and some will use an aggregate base placed on compacted subgrade. The aggregate base will be covered with one or more layers of asphalt. The table below is the minimum pavement designs. Each layer is the compacted thickness. At no time should less than 4 inches of an aggregate subbase layer be used. In addition, most homeowners will not have a soil strength test performed on their subgrade. Therefore, for silty and clayey soils, a medium or weak subgrade should be assumed. For sandy and gravelly/rocky subgrade, a strong or medium subgrade should be assumed.

Table 1 – Full-Depth Asphalt Pavement

Table 2 – Asphalt with Aggregate Sub-Base Pavement

Notes:

- Design CBR is defined as 2/3 of the soaked CBR value.

- VDOT Specifications for SM-4.75, SM-9.0, SM-9.5, SM-12.5, and IM-19.0 can be found in Section 211 of the 2016 VDOT Road and Bridges Specification Book.

- VDOT Specifications for 21B can be found in Section 208 of the 2016 VDOT Road and Bridges Specification Book.

Future Maintenance Considerations

In time, pavement failures may occur due to settlement or weakening of the soil or aggregate base layers. These will result in localized failures or potholes. To repair these failures, the area impacted should be cut out and the pavement material removed to the subgrade. The subgrade material may need to be removed and replaced or simply recompacted. Finally, the removed pavement material should be replaced with new asphalt concrete or a permanent asphalt patching material.

As asphalt ages, shrinkage cracks will develop. Individual transverse and longitudinal cracks should be sealed with an asphalt-based material to reduce the amount of water infiltrating the underlying pavement layers. If the cracking is extensive, then the pavement can be overlaid with a new AC surface or removed and replaced with a new AC surface. Overlaying can be performed on driveways without curb and gutter. For driveways with curb and gutter, milling or asphalt removal may be needed to maintain surface drainage.

Surfacing Existing Aggregate and Gravel Driveways

In many ways, the surfacing of an existing aggregate or gravel driveway removes many of the issues associated with a new driveway. Existing driveways have been subjected to repeated loadings, so the subgrade and aggregate/gravel layers should be compacted and minimal or no future settlement should be expected. However, before the existing driveway is surfaced with asphalt concrete, the homeowner should do the following:

- Verify the existing aggregate/gravel layer is at least 4” thick.

- Make sure the existing aggregate/gravel layer is graded to remove low and high spots in order to provide a level paving surface.

- Applied a soil sterilizing agent to prevent future vegetation.

- Removed existing vegetation prior to surfacing.

Once these steps have been performed, then the pavement structures provided in Table 2 can be used for a minimum asphalt concrete thickness.

References

- 2016 VDOT Road and Bridges Specifications

- VDOT Special Provisions to the 2016 Road and Bridges Specifications

- VAA Pavement Design Manual