Please note – The following information covers the basic components of building durable economical asphalt sidewalks and playgrounds. Individual designs should be based on intended use, aesthetics, and available funds. Properly constructed asphalt sidewalks and play areas will provide excellent service for many years.

Please note – The following information covers the basic components of building durable economical asphalt sidewalks and playgrounds. Individual designs should be based on intended use, aesthetics, and available funds. Properly constructed asphalt sidewalks and play areas will provide excellent service for many years.

Design Considerations

The width of the sidewalk or walkway should be determined from the anticipated foot traffic. However, the minimum width should be at least three feet (3′) to permit two people to walk abreast with widths of four to five feet (4-5′) being preferable. Where curved walkways are used, the additional width should be incorporated in the curves.

Subgrade Preparation

Because the subgrade must serve both as a working platform to support construction equipment and as the foundation for the pavement structure, it is most important to see that the subgrade is properly compacted and graded. A visual examination will usually reveal the adequacy of elevation. Laboratory tests to evaluate the load-supporting characteristics of subgrade soil are desirable. If these tests are not available, designs may be chosen based on careful field evaluations and previous projects and experience in the area. All underground utilities should be protected or relocated prior to grading. All topsoil should be removed and low-quality soils must be improved by adding asphalt or other suitable admixtures such as lime or granular materials.

Because the subgrade must serve both as a working platform to support construction equipment and as the foundation for the pavement structure, it is most important to see that the subgrade is properly compacted and graded. A visual examination will usually reveal the adequacy of elevation. Laboratory tests to evaluate the load-supporting characteristics of subgrade soil are desirable. If these tests are not available, designs may be chosen based on careful field evaluations and previous projects and experience in the area. All underground utilities should be protected or relocated prior to grading. All topsoil should be removed and low-quality soils must be improved by adding asphalt or other suitable admixtures such as lime or granular materials.

The area to be paved should be treated with a soil sterilizing agent to inhibit future flora growth after all rock, debris, and vegetation matter has been removed. Grading and compaction of the area should be completed in such a manner as to prevent yielding areas or pumping of the soil (A large truck driven over the area will give an indication of any “soft spots”). Should a weak spot be discovered, the material should be removed and replaced with six inches (6″) compacted crushed stone or three inches (3″) compacted asphalt concrete. In case of extremely poor subgrade, it may be necessary to remove the upper portion of the subgrade and replace it with the selected material. When finished, the graded subgrade should not deviate from the required grade and cross section by more than one-half inch (1/2”) in ten feet (10′).

Drainage Provisions

It is most important to keep water away from the subgrade soil. If the soil becomes saturated it will lose strength and stability and make the overlying pavement structure susceptible to break up under imposed loads. Both surface and subsurface drainage must be considered. All drainage must be carefully designed and should be installed in the construction process as early as is practicable. Sidewalks and walkways should follow the contour of the terrain so that surface water runs off the pavement and away from it. Playgrounds and fiat sidewalks should have a minimum slope of two percent (2%) or one-quarter inch (1/4”) per foot (1 ‘) and be constructed in such a manner that water will not collect at the pavement edge. Areas of very high natural permeability may require an underdrain system to carry water away from the pavement structure. (Note: underdrains are usually not necessary when asphalt is used for the base and surface courses.)

Base Construction (Asphalt)

Prior to placement of the asphalt concrete base course, the subgrade should be graded to the established requirements, adequately compacted, and all deficiencies corrected. The asphalt concrete base course should be placed directly on the prepared subgrade in one or more lifts, spread, and compacted to the pavement thickness indicated on the plans or established in the contract. (Compaction of asphalt mixtures is one of the most important construction operations contributing to the proper performance of the completed pavement, regardless of the thickness of the course being placed. This is why it is so important to have a properly prepared subgrade against which to compact the overlying pavement.) The asphalt concrete should meet the Virginia Department of Transportation specifications for the mix type specified.

Base Construction (Aggregate)

The subgrade must be graded to the required contours and grade in such a manner as will ensure a hard, uniform, well-compacted pavement structure. All subgrade deficiency corrections and drainage provisions should be made prior to constructing the aggregate base. The crushed aggregate base course should consist of one or more layers placed directly on the prepared subgrade, spread, and compacted to the uniform thickness and density as required on the plans or established by the owner. Absolute minimum crushed aggregate thickness is four inches (4″). All crushed aggregate material should be of Virginia Department of Transportation approved type and suitable for this type of application.

Tack Coat (if needed)

Prior to placement of successive pavement layers, the previous course should be cleaned and, if needed, a tack coat of diluted emulsified asphalt applied. The tack coat may be eliminated if the previous course is freshly placed and thoroughly clean.

Asphalt Surface Course

Material for the surface course should be asphalt concrete placed in one or more lifts to the true line and grade as shown on the plans or set by the architect or engineer. The asphalt concrete should conform to Virginia Department of Transportation specifications for the type specified. The asphalt surface should not vary from established grade by more than one-eighth inch (1/8”) in ten feet (10′) when measured in any direction. Any irregularities in the surface of the pavement course should be corrected directly behind the paver. Rolling and compaction should start as soon as the asphalt concrete can be compacted without displacement and continued until thoroughly compacted and all roller marks disappear.

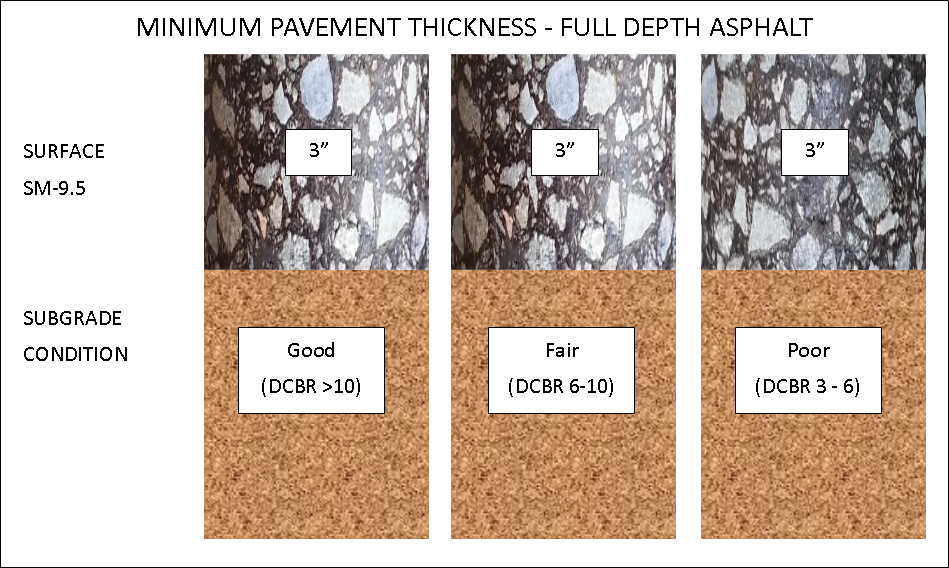

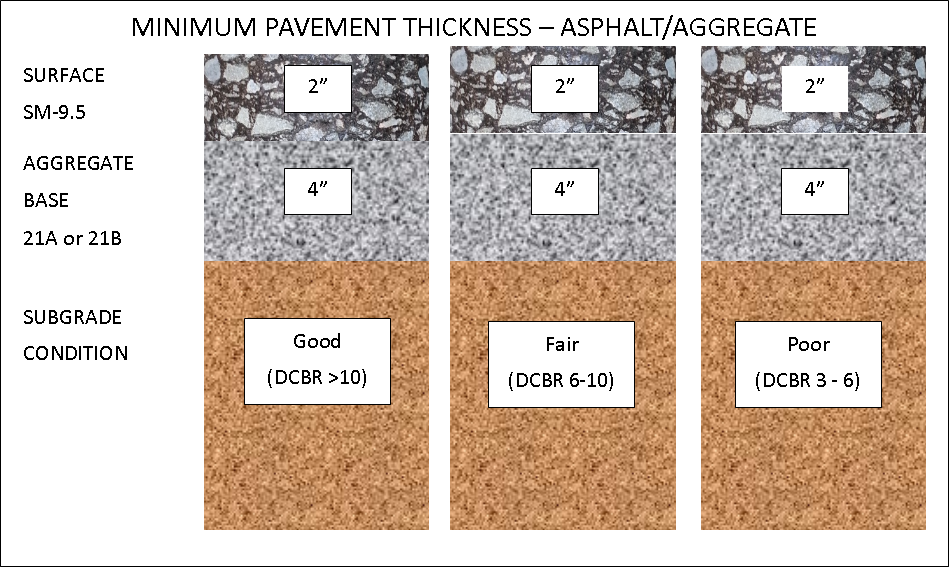

Pavement Structure

The pavement structure and materials are common across subgrade strengths and construction approaches. Some projects will use full-depth asphalt (i.e., asphalt placed directly on compacted subgrade) and some will use an aggregate base placed on compacted subgrade. The aggregate base will be covered with one or more layers of asphalt. The table below is the minimum pavement designs. Each layer is the compacted thickness. At no time should less than 4 inches of an aggregate subbase layer be used. In addition, most owners will not have a soil strength test performed on their subgrade. Therefore, for silty and clayey soils, a medium or weak subgrade should be assumed. For sandy and gravelly/rocky subgrade, a strong or medium subgrade should be assumed.

Table 1 – Full-Depth Asphalt Pavement

Table 2 –Asphalt with Aggregate Sub-Base Pavement

Notes:

- Design CBR is defined as 2/3 of the soaked CBR value.

- VDOT Specifications for S-5 can be found in 1994 Specifications Manual Section 211

- VDOT Specifications for SM-2A can be found in 1987 Specifications Manual Section 212

- VDOT Specifications for SM-4.75, SM-9.0, SM-9.5, and SM-12.5 can be found in Section 211 of the 2016 VDOT Road and Bridges Specification Book.

- VDOT Specifications for 21B can be found in Section 208 of the 2016 VDOT Road and Bridges Specification Book.

References

2016 VDOT Road and Bridges Specifications

VDOT Special Provisions to the 2016 Road and Bridges Specifications