Please Note – Collector or feeder streets carry traffic from the residential streets to the arterial routes and provide direct access to subdivisions from arterial streets and roads. Generally, they have moderate amounts of low-speed traffic and include some bus and truck traffic. As with residential street design, most localities have adopted design standards for the construction of collector streets. All applicable local and state codes, standards, and specifications should be strictly followed when designing and constructing these streets. The information contained on this page should serve as additional considerations in the proper planning and design of collector and feeder streets.

Please Note – Collector or feeder streets carry traffic from the residential streets to the arterial routes and provide direct access to subdivisions from arterial streets and roads. Generally, they have moderate amounts of low-speed traffic and include some bus and truck traffic. As with residential street design, most localities have adopted design standards for the construction of collector streets. All applicable local and state codes, standards, and specifications should be strictly followed when designing and constructing these streets. The information contained on this page should serve as additional considerations in the proper planning and design of collector and feeder streets.

Design Considerations

As is the case in planning all types of roadway facilities, it is absolutely essential that maximum safety features be built into street systems. Right angle intersections provide better visibility in all directions for the driver, as well as shorter crossing distances. The installation of underground wiring for electric and telephone utilities is desirable for both safety and aesthetics. Consideration should be given to using a two-layer asphalt pavement design. This type of pavement permits the use of the facility during the construction process and permits the repair of any failed areas prior to placing the final surface.

Most pavement designs are based on the traffic using the road when the construction and over a specific design life. However, for many roads, especially those with light to moderate traffic, the heaviest traffic using the road is during the construction phases of connected subdivisions.

Most pavement designs are based on the traffic using the road when the construction and over a specific design life. However, for many roads, especially those with light to moderate traffic, the heaviest traffic using the road is during the construction phases of connected subdivisions.

Therefore, the pavement loading for these types of pavement structures should be adjusted based on the construction traffic and it is recommended these pavements be built in phases. The first phase is the placement of the aggregate sub-base and asphalt base layer(s) on the prepared subgrade (or in the case of full-depth asphalt pavements, placing the asphalt base layer(s) directly on the prepared subgrade). The final riding surface should not be placed until all construction of adjacent subdivisions has been substantially completed.

Because of the heavy trucks and construction traffic, pavement failures of portions of the first phase can occur. Under the second phase, any needed repairs should be noted and repaired then the final surface placed on the roadway.

|  |  |

The two most important considerations in designing a pavement are traffic and drainage. If either is not adequately accounted for in the pavement design, the pavement structure will either be over-designed (and money wasted) or under designed (and result in premature and continual maintenance).

Traffic Analysis

Asphalt pavements must be designed using proper loading data to ensure adequate pavement performance. In collector street design, this data should be based on vehicular traffic estimates for the pavement’s design life. These estimates should include accurate counts of vehicles by type, weight, and number. This Design Manual considers collector streets to be medium duty streets with traffic, both present and future, mostly passenger cars but with some truck and bus traffic. These streets require a thicker pavement structure compared to the surrounding subdivisions and adjacent streets. Any deviation from this assumption will require adjustments to the pavement designs shown in the table below.

The effects of truck traffic on pavement life can be dramatic. Test results have shown that a single, fully loaded, an 80,000-pound truck can cause the equivalent in pavement wear of 9,600 automobiles. While these test results may only approximate wear caused by heavy vehicles, they do illustrate why estimating traffic type and number is important in determining the proper asphalt pavement design.

The effects of truck traffic on pavement life can be dramatic. Test results have shown that a single, fully loaded, an 80,000-pound truck can cause the equivalent in pavement wear of 9,600 automobiles. While these test results may only approximate wear caused by heavy vehicles, they do illustrate why estimating traffic type and number is important in determining the proper asphalt pavement design.

Drainage

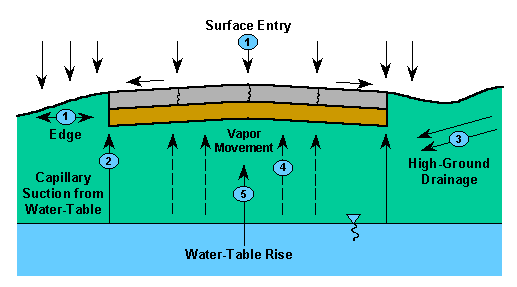

Adequate pavement drainage is of great importance to all pavement designs. If the subgrade under the pavement becomes saturated, it will lose strength and stability and make the overlying pavement structure susceptible to break up under imposed loads. Both surface and subsurface drainage must be considered. All drainage must be carefully designed and should be installed in the construction process as early as is practicable. The pavement should also be constructed in a manner that will not permit water to collect at the pavement edge and provisions should be made to intercept all groundwater from springs, seepage planes, and streams. When used, curb and gutter sections should be set to true line and grade. Marshy areas will require special consideration and should be addressed during the planning stage.

Drainage impacts pavement performance when the subgrade materials and pavement layer materials are saturated and lose strength. Water that falls on the pavement surface must be drained to curb and gutter systems or ditches. Water that penetrates the pavement from the surface; infiltrates from the sides of the road, or rises from under the pavement should not be allowed to compromise the overall strength.

Every effort should be made to prevent surface water from crossing streets at intersections. Not only is there a danger of hazardous stopping of traffic, the street depression necessary to permit drainage to cross the intersection restricts vehicular movement due to the low speed required to negotiate it.

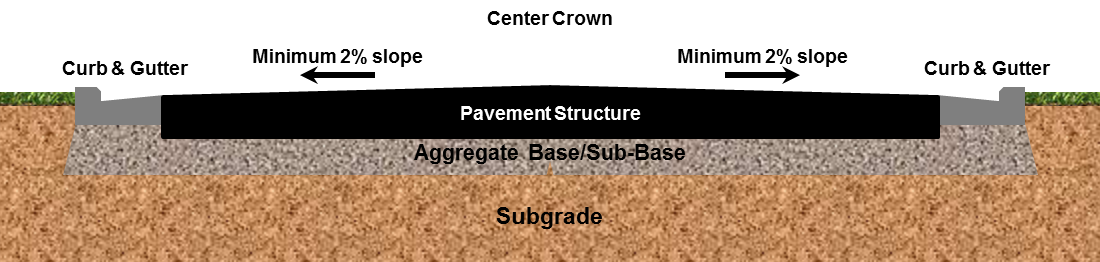

To account for surface water drainage, it is important that the road is constructed with a crown or cross slope. Typically, a crown is placed in the center of the road and the pavement is sloped 2% in each direction. Occasionally, the pavement will be super-elevated where one side of the road is higher than the other. In either case, the pavement must be sloped to keep water from ponding on the surface.

For subsurface water, the approach to address varies based on the project. In some situations, underdrains are placed to intercept water that may flow under a pavement. This water is then allowed to flow out into a ditch or is put in a stormwater system. In many cases where the subgrade becomes weaker due to water, the subgrade is stabilized with a binding agent, removed and replaced with a stronger material, covered with a stabilization fabric prior to placing the next pavement layer or the next pavement layers are made thicker.

Soil Support

The ability of the native subgrade soil to support loads transmitted through the pavement is one of the most important factors in determining pavement thickness. Prior to construction or developing the project plans, the subgrade should be sampled and tested for strength. The primary strength parameter for subgrade soil is the California Bearing Ratio or CBR and quantifies how well the soil can withstand traffic loads. The CBR test provides a simple and dependable index of a soil’s load-bearing capacity, the lower the value, the less strength the soil has. It is widely used by many highway departments as well as other governmental agencies on both the state and federal levels.

Overall, all projects should be sampled and tested by a qualified engineering firm. The number of samples will depend on the length of the road and the changes in soil type. VDOT testing manuals can be consulted for recommended testing rates.

However, the designer should be aware of the limitations of using averaged CBR values in determining soil support data. Up to one-third of the soil samples used to compute an average CBR will be below that value.

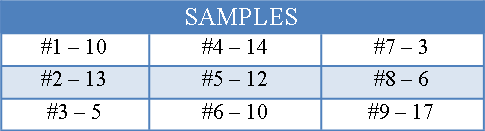

Example:

Nine CBR samples are taken on a proposed subdivision street in Richmond and their values are as follows:

The average CBR value for these samples is 10. However, samples #3, 7 and 8 were well below 10. If the pavement is designed based on an average CBR value of 10, pavement failure in the areas of test samples 3, 7 and 8 can be expected.

This Manual recommends a Design CBR value of two-thirds (2/3) the actual average CBR value be used in selecting pavement thickness (the Vaswani design method used by The Virginia Department of Transportation also uses a design value of two thirds (2/3) the average CBR value). This will help assure the adequacy of the pavement design.

In general, a design CBR value of 3 or less indicates a poor soil. Soils with this value should be removed to a depth of 12 inches to 18 inches and replaced with a stronger material, or stabilized with additives such as lime or cement to a depth between 6 inches and 12 inches.

ASTM Standard Test Method D 1883

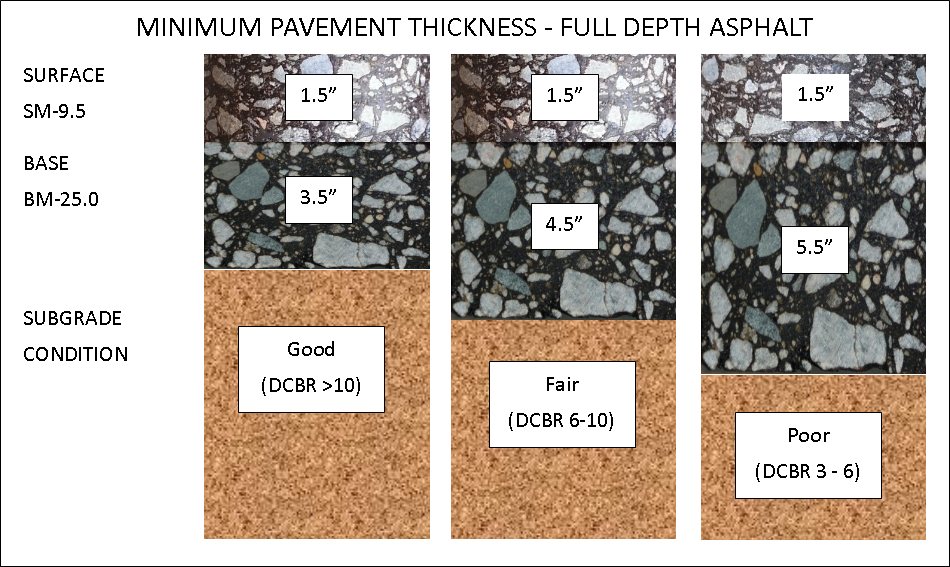

Pavement Thickness

The values for pavement thickness given in this Chapter are minimum compacted thicknesses. Any reduction of the pavement thickness values shown for base or surface may cause severe pavement failure and/or a shorter pavement life.

Subgrade Preparation

Because the subgrade must serve both as a working platform to support construction equipment and as the foundation for the pavement structure, it is most important to see that it is properly compacted and graded. Laboratory tests to evaluate the load supporting characteristics of subgrade soil are required. Test data for the area may be available from the Virginia Department of Transportation’s local office.

All underground utilities should be protected or relocated prior to grading. All topsoil should be removed and low-quality soil must be improved by adding asphalt or other suitable admixtures such as lime or granular materials.

The areas to be paved should have all rock, debris, and vegetation matter removed. Grading and compaction of the area should be completed in such a manner as to prevent yielding areas or pumping of the soil. The subgrade should be compacted to a uniform minimum density of 95% of the maximum theoretical density.

Should a weak spot be discovered, the material should be removed and replaced with either six inches (6″) compacted crushed stone; or three inches (3″) compacted asphalt concrete. In case of extremely poor subgrade, it may be necessary to remove the upper portion of the subgrade and replace it with a select material. When finished, the graded subgrade should not deviate from the required grade and cross section by more than one-half inch (1/2”) in ten feet (10′).

Base Construction (Asphalt)

Prior to placement of the asphalt concrete base course, the subgrade should be graded to the established requirements, adequately compacted, and all deficiencies corrected. The asphalt concrete base course should be placed directly on the prepared subgrade in one or more lifts, spread, and compacted to the pavement thickness indicated on the plans or established by the owner.

Compaction of asphalt mixtures is one of the most important construction operations contributing to the proper performance of the completed pavement, regardless of the thickness of the course being placed. This is why it is so important to have a properly prepared subgrade against which to compact the overlying pavement. The asphalt concrete should meet the Virginia Department of Transportation specifications for the mix type specified.

Base Construction (Aggregate)

The subgrade must be graded to the required contours and grade in a manner that will ensure a hard, uniform, well-compacted surface. All subgrade deficiency corrections and drainage provisions should be made prior to constructing the aggregate base.

The crushed aggregate base course should consist of one or more layers placed directly on the prepared subgrade, spread, and compacted to the uniform thickness and density as required on the plans or established by the owner. The absolute minimum crushed aggregate thickness is six (6″). All crushed aggregate material should be of Virginia Department of Transportation approved type and suitable for this type of application.

Tack Coat

Prior to placement of successive pavement layers, the previous course should be cleaned and, if needed, a tack coat of diluted emulsified asphalt applied. If the previous course is freshly placed and thoroughly clean, the tack coat may be eliminated.

Asphalt Surface Course

Material for the surface course should be asphalt concrete placed in one or more lifts to the true line and grade as shown on the plans or set by the owner. The asphalt concrete should conform to Virginia Department of Transportation specifications for asphalt concrete. The Asphalt surface should not vary from established grade by more than one-quarter inch (1/4”) in ten feet (10′) when measured in any direction. Any irregularities in the surface of the pavement course should be corrected directly behind the paver. Rolling and compaction should start as soon as the asphalt concrete can be compacted without displacement and continued until thoroughly compacted and all roller marks disappear.

Curb and Gutter

Designed to provide roadway drainage, curb and gutters also delineate the roadway edge. Gutter widths vary from one (1’) to two (2’) feet, with a one and-one-half (1 ½’) foot width being most common. Vertical curbs range between five (5”) and eight (8”) inches in height, with a six (6”) inch high curb preferred.

One of the most common errors in pavement design is not specifying the appropriate grades to ensure that water does not collect on the pavement. On many collector streets, the elevation of the pavement is below that of the curb and gutter. As water is the biggest enemy of any pavement, these “dry curbs” will result in poor pavement performance and shorter pavement life.

Pavement Structure

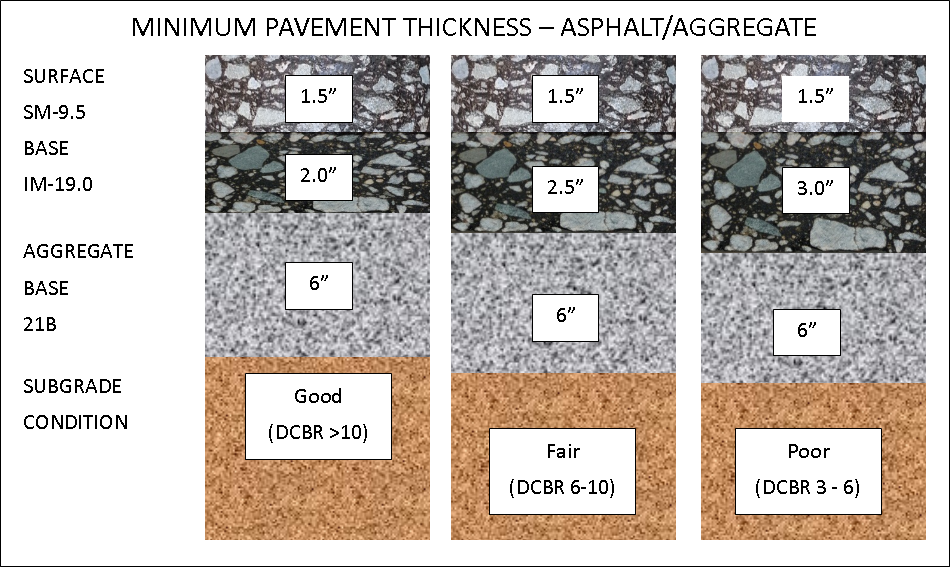

The pavement structure and materials used will change as a function of subgrade strength and construction approach. Some projects will use full-depth asphalt (i.e., asphalt placed directly on compacted subgrade) and some will use an aggregate base placed on compacted subgrade. The aggregate base will be covered with one or more layers of asphalt. The table below is the minimum pavement designs. Each layer is the compacted thickness. At no time should less than 4 inches of an aggregate subbase layer be used.

Table 1 – Full-Depth Asphalt Pavement

Table 2 –Asphalt with Aggregate Sub-Base Pavement

Notes:

- Design CBR is defined as 2/3 of the soaked CBR value.

- VDOT Specifications for SM-4.75, SM-9.0, SM9.5, IM-19.0, and BM-25.0 can be found in Section 211 of the VDOT Road and Bridges Specification Book.

- VDOT Specifications for 21B can be found in Section 208 of the VDOT Road and Bridges Specification Book.

Future Maintenance Considerations

In time, pavement failures may occur due to settlement or weakening of the soil or aggregate base layers. These will result in localized failures or potholes. To repair these failures, the area impacted should be cut out and the pavement material removed to the subgrade. The subgrade material may need to be removed and replaced or simply recompacted. Finally, the removed pavement material should be replaced with new asphalt concrete or a permanent asphalt patching material.

As asphalt ages, shrinkage cracks will develop. Individual transverse and longitudinal cracks should be sealed with an asphalt-based material to reduce the amount of water infiltrating the underlying pavement layers. If the cracking is extensive, then the pavement can be overlaid with a new AC surface or milled and replaced with a new AC surface. Overlaying can be performed on streets without curb and gutter. For streets with curb and gutter, milling may be needed to maintain surface drainage. While edge milling can be performed, typically 4 to 6 feet in width at the edge of the road, full pavement milling is recommended in order to keep proper cross-slope.

References

2016 VDOT Road and Bridges Specifications

VDOT Special Provisions to the 2016 Road and Bridges Specifications

VAA Pavement Design Manual