Please note – The following information serves as a general guide for the design, orientation, layout, and construction of tennis court(s) using asphalt concrete. This information will be of particular value to those who do not have a detailed knowledge of the construction of tennis court facilities and it will aid in maintaining high standards. Sample construction specifications may be found in another section of this website.

Please note – The following information serves as a general guide for the design, orientation, layout, and construction of tennis court(s) using asphalt concrete. This information will be of particular value to those who do not have a detailed knowledge of the construction of tennis court facilities and it will aid in maintaining high standards. Sample construction specifications may be found in another section of this website.

Additional information and guide specifications for the construction of Asphalt tennis courts are available from the American Sports Builders Association.

Court Orientation

Through the careful analysis of sun angles, it has been determined that the most comfortable angle for court setting is 22° South-East and North-West for the length of the court off true North-South. This permits each side of the court to have equal sun angles, which is assumed to be the ideal outdoor playing condition as far as the effect of glare is concerned.

Subgrade Preparation

A soil examination should be made to determine its suitability as a foundation material. Trees and other vegetation including their root systems must be removed from the site and the soil treated with a sterilizing agent that will effectively inhibit future flora growth. Because the earth subgrade must serve both as a working platform to support construction equipment and as the foundation for the pavement structure, it is most important to see that the subgrade is properly compacted and graded. All topsoil should be removed and low-quality soils must be improved by adding asphalt or other suitable admixtures such as lime or granular materials.

The site should be excavated and filled to provide the finished grades shown on the plans or established by the owner. Any soft, yielding material should be replaced with a suitable material is not greater than six inch (6″) lifts and compacted to a density of 95 percent (95%) standard density at optimum moisture. Good compaction is particularly important in tennis court construction, as subsequent settlement of the subgrade may cause cracking in the court surface. The subgrade should be shaped to true and even lines so as to ensure a uniform thickness of base course. Subgrade surface should have a maximum variance of plus or minus 1/2”.

The site should be excavated and filled to provide the finished grades shown on the plans or established by the owner. Any soft, yielding material should be replaced with a suitable material is not greater than six inch (6″) lifts and compacted to a density of 95 percent (95%) standard density at optimum moisture. Good compaction is particularly important in tennis court construction, as subsequent settlement of the subgrade may cause cracking in the court surface. The subgrade should be shaped to true and even lines so as to ensure a uniform thickness of base course. Subgrade surface should have a maximum variance of plus or minus 1/2”.

Drainage and Slope Provisions

Proper drainage is of the utmost importance in the construction of a good court. In sandy or gravelly soil, subsurface drainage may not be required, but in areas of predominantly clay soils, a perimeter drain (French drain) consisting of a perforated pipe or clay tile backfilled with crushed stone in a two to three-foot deep ditch around the court(s) is recommended. When asphalt concrete is used for both base and surface, underdrains are usually not required. The perimeter drainage ditch should have adequate slope and outlets to prevent the retention of water.

In order to properly drain, the finished court surface(s) should have a minimum slope of one inch (1″) in every ten feet (10′) on a true plane from side to side, end to end, or corner to corner. The 12″ difference in elevation from one end to the other (8″ in the in-bounds area) is not noticeable by the players. The surface should not slope away in two directions from the net.

Perimeter Edging

An edging of brick, concrete, steel, or treated wood should be installed around the entire perimeter of the court area. Top elevation of the edging should be one-half Inch (1/2”) below the finished grade level and the court’s surface course should be tapered from six inches (6″) out to meet it.

Base Construction (Asphalt)

The asphalt concrete should meet the Virginia Department of Transportation specifications for the type of mix specified. The specified thickness of asphalt concrete should be placed in one lift on the prepared subgrade. The material as thus spread should be compacted to the required uniform density by rolling with a powered steel wheel tandem roller weighing eight to ten (8-10) tons or by other equipment producing equivalent density. The finished base should conform to the true lines and grade as established on the plans or by the owner with a variance of not more than one-half inch (/12”) when measured with a ten foot (10′) straight edge.

Base Construction (Aggregate)

The crushed aggregate should be placed and compacted to a uniform thickness and required density with a maximum grade variance of one-half inch (1/2”) in ten feet (10′) measured in any direction. All aggregate material should conform to Virginia Department of Transportation specifications. Compaction in the construction operation is most important to the performance of the completed asphalt pavement, regardless of the thickness of the course being placed. Compaction should be accomplished by rolling with an eight to ten (8-10) ton powered steel wheel roller or other equipment capable of producing equivalent density. Under no circumstances should the compacted aggregate thickness be less than four inches (4″).

Tack Coat (if needed)

Prior to placement of successive pavement layers, the previous course should be cleaned and, if needed, a tack coat of diluted emulsified asphalt applied. The tack coat may be eliminated if the previous course is freshly placed and thoroughly clean.

Asphalt Surface Course

Material for the surface course should be asphalt concrete placed in one or more lifts to the true line and grade as shown on the plans or set by the owner. The asphalt concrete should conform to Virginia Department of Transportation specifications for the asphalt concrete specified. The Asphalt surface should not vary from established grade by more than one-eighth inch (1/8”) in ten feet (10’) when measured in any direction.

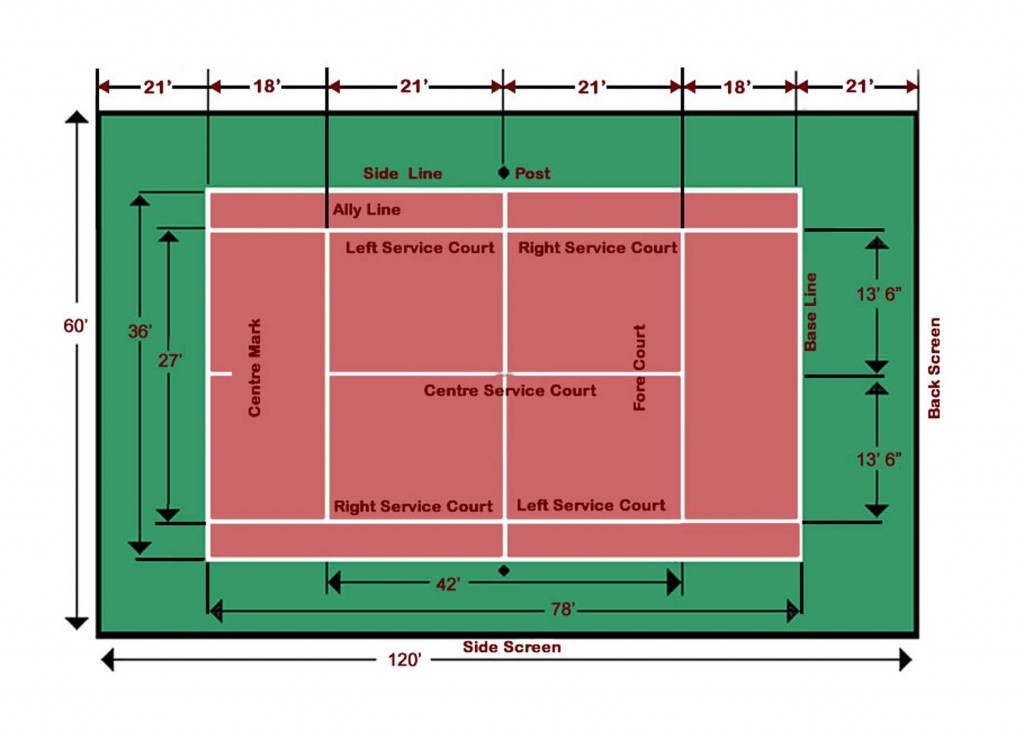

Layout

The basic layout of a tennis court and dimensions are illustrated below. Post foundations should be twenty-four inches (24″) in diameter at the top, thirty (30”) inches in diameter at the bottom, and not less than thirty-six (36″) in depth. The dimension between posts is thirty-three feet (33′) on single courts and forty-two feet (42′) on double courts. New posts are galvanized, two and seven-eighths inches (27/s”) In diameter and equipped with a net tightening device. The standard net is forty-two feet (42′) in length and three feet three inches (3′-3″) high.

Color Finish Course (Optional):

The use of a color finish on asphalt tennis court surfaces is becoming increasingly popular. Frequently used colors are grass green and tile red, or a combination of the two. Prior to the addition of any color course, the entire surface should be flooded with water and allowed to drain. Any depression that holds water deeper than one-eighth inch (1/8”) should be patched. There is a wide variety of color surfaces available for tennis court construction. Color surface manufacturer’s specifications should be followed for the addition of any color or textured surface.

Playing Lines

A minimum of thirty days (30) waiting time following construction is recommended before the application of playing lines. A latex striping paint should be used and placed no thicker than necessary for delineation. Baselines should not be more than four inches (4″) wide and playing lines not more than two inches (2″) wide, accurately located and marked in accordance with the rules of the United States Lawn Tennis Association. If a color finish has been applied, the striping paint should be of a manufacturer and type recommended by the surface coating manufacturer, painted in accordance with the paint manufacturer’s standard specifications. Traffic, oil, alkyd, or solvent-type paints should not be used.

Tennis Court Overlays

There are many reasons for overlaying an existing tennis court, such as surface oxidation or aging, poor drainage, or poorly constructed base. Each of these conditions and their severity should be considered in determining the required overlay pavement thickness. Since there are many possible considerations in determining the most sound and economical procedures to follow in resurfacing a tennis court, it is strongly recommended that a qualified asphalt paving contractor, experienced in tennis court construction, be consulted.

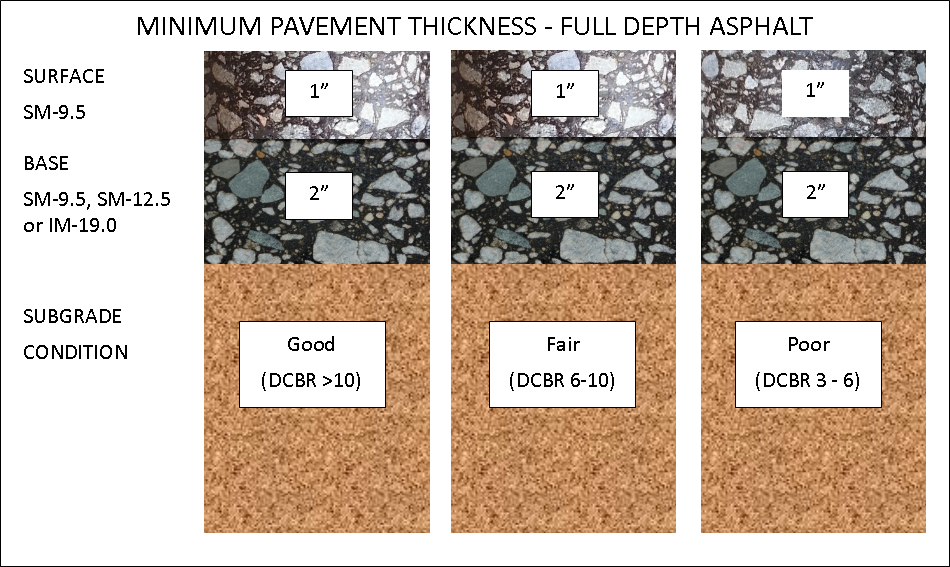

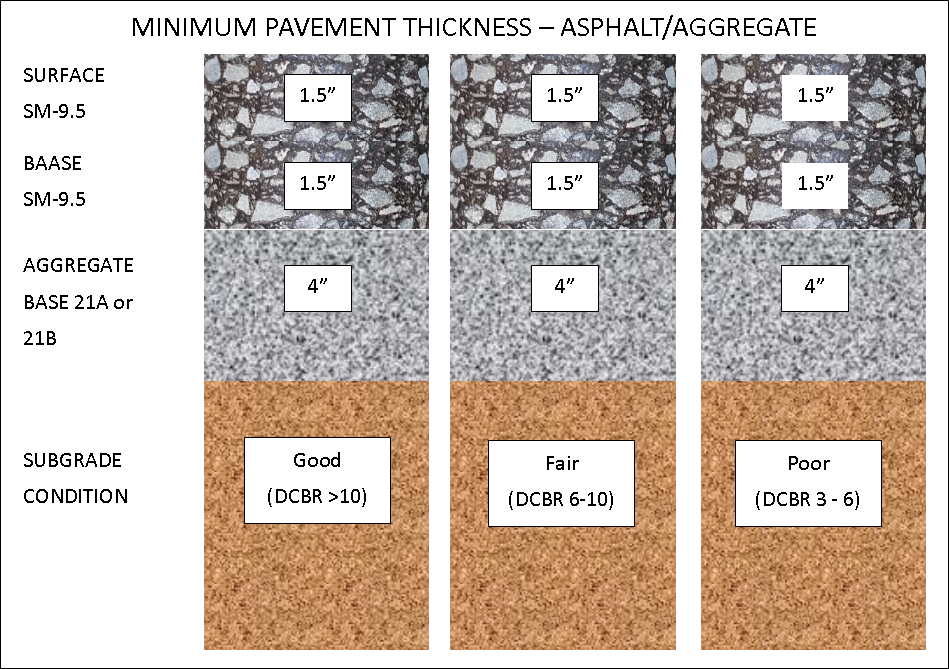

Pavement Structure

The pavement structure and materials are common across subgrade strengths and construction approaches. Some projects will use full-depth asphalt (i.e., asphalt placed directly on compacted subgrade) and some will use an aggregate base placed on compacted subgrade. The aggregate base will be covered with one or more layers of asphalt. The table below is the minimum pavement designs. Each layer is the compacted thickness. At no time should less than 4 inches of an aggregate subbase layer be used. In addition, most owners will not have a soil strength test performed on their subgrade. Therefore, for silty and clayey soils, a medium or weak subgrade should be assumed. For sandy and gravelly/rocky subgrade, a strong or medium subgrade should be assumed.

Table 1 – Full-Depth Asphalt Pavement

Table 2 –Asphalt with Aggregate Sub-Base Pavement

Notes:

- Design CBR is defined as 2/3 of the soaked CBR value.

- VDOT Specifications for SM-4.75, SM-9.0, SM-9.5, and SM-12.5 can be found in Section 211 of the 2016 VDOT Road and Bridges Specification Book.

- VDOT Specifications for 21B can be found in Section 208 of the 2016 VDOT Road and Bridges Specification Book.

References

2016 VDOT Road and Bridges Specifications

VDOT Special Provisions to the 2016 Road and Bridges Specifications